Technology

DMG® Technology by Powerhouse Energy

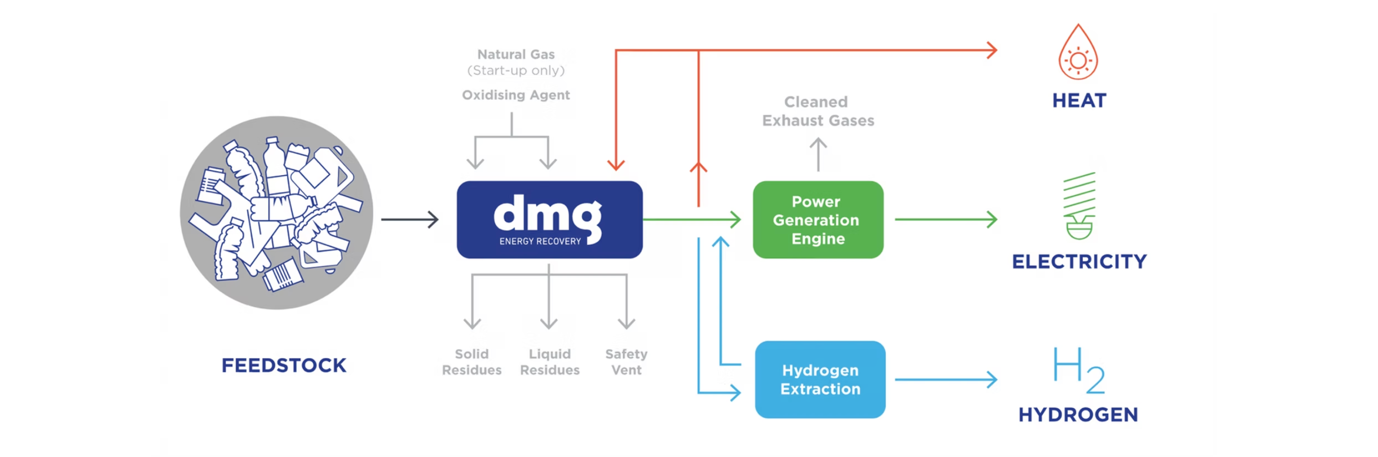

Distributed Modular Generation (DMG®) is an advanced and innovative platform designed for the conversion of non-recyclable waste plastics into clean energy. This cutting-edge technology regenerates plastic waste into power or hydrogen, providing a sustainable energy solution for transport, industrial applications, and the chemical and plastics industries.

Developed by Powerhouse Energy, DMG® represents a breakthrough in waste-to-energy technology, offering an efficient and environmentally responsible alternative for tackling plastic waste while supporting the transition to clean energy.

Powerhouse Energy Group plc is a publicly traded company listed on the London Stock Exchange’s AIM market under the ticker symbol PHE.